キングモア・ラッキング、ベトナムのDDKグループにシャトル・ラッキング・システムを納入

Nov 12, 2025プロジェクト概要

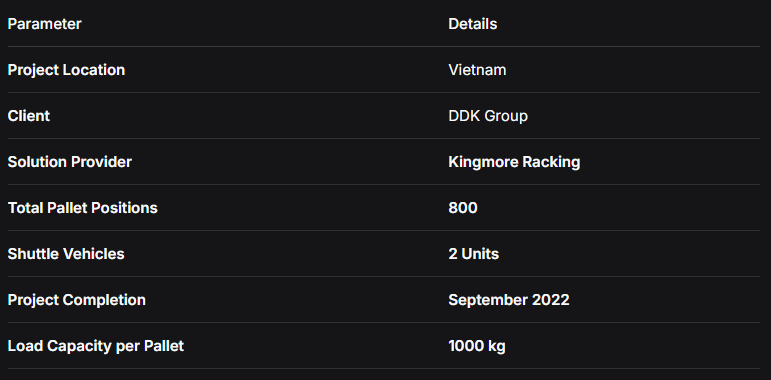

ストレージ機器のリーディングメーカーであるキングモア・ラッキングは、ベトナムのDDKグループ向けに高性能な半自動シャトルラックシステムを設計・導入したことを誇りに思います。2022年9月に無事に稼働を開始したこのプロジェクトにより、クライアントの倉庫は高密度・高効率のストレージ施設へと変貌し、物流における主要な課題に効果的に対処しました。

|  |

クライアントの課題

DDK グループでは、倉庫業務における重大なボトルネックを克服するためのソリューションを必要としていました。

不十分な保管容量: 従来のラックでは、既存のスペース内で増大する在庫需要を満たすことができませんでした。

非効率的な運用: 手動のプロセスとフォークリフトの移動距離が長いため、在庫処理が遅くなります。

高い運用コスト: 人件費の上昇とピーク時の人為的ミスの可能性が大きな懸念事項でした。

耐久性要件: 最大 1,000kg の重さのパレットを安全に取り扱うには、堅牢なソリューションが必要でした。

当社のソリューション:キングモアシャトルラックシステム

Kingmore Rackingは、自社製造の半自動シャトルラックシステムを中心としたターンキーソリューションを提供しました。このアプローチは、堅牢なエンジニアリングとスマートテクノロジーを融合させ、スペースとワークフローを最適化しました。

システムコアコンポーネント:

Kingmore の頑丈なラック: 高品質の鋼鉄を使用して社内で設計、製造されており、パレットあたり 1,000 kg の荷重要件を満たす優れた強度と長期的な信頼性を確保します。

無線シャトル車両(2 台):このシステムは、ラック レーン内のレール上で動作する 2 台の高性能シャトル カーを統合し、パレットの配置と取り出しを自動化します。

プロフェッショナルな統合とサポート: 当社の包括的なサービスには、最適なパフォーマンスを確保するためのシステム設計、インストール、試運転、オペレーターのトレーニングが含まれています。

運用ワークフロー:

フォークリフトのオペレーターは、レーンの入口にパレットを置くだけで済みます。リモコンでシャトルカーを呼び出し、荷物をレーンの奥まで自動的に運び、保管します。取り出しは、この逆の手順で行います。この「Goods-to-Person(商品から人へ)」の原理により、フォークリフトの混雑、待ち時間、通路内での移動が大幅に削減され、速度と安全性が向上します。

主なプロジェクト仕様

スペースを最大限に活用: 高密度設計により、従来のラックに比べて保管容量が 70% 以上増加し、倉庫の設置面積に対する収益が最大化されました。

効率が劇的に向上: 2 台のシャトルによる並行操作により、高速で大量のスループットが可能になり、注文処理が大幅に加速されました。

最適化された運用コスト: このシステムにより、フォークリフトの集中的な使用と複数のオペレーターへの依存が軽減され、人件費とエネルギーコストが大幅に削減されました。

安全性と精度の向上:フォークリフトと歩行者の接触を最小限に抑えることで安全性が向上しました。また、体系的な保管と取り出しにより、正確な在庫管理と棚卸しの簡素化が実現しました。

結論

DDKグループ向けシャトルラックプロジェクトの成功は、キングモア・ラッキングが国際市場向けにカスタマイズされた高品質な保管ソリューションを提供できる能力の証です。クライアントの当面の運用上の課題を解決しただけでなく、将来を見据えた倉庫運営の実現にも貢献しました。

Kingmore Rackingは、設計、製造、設置まで、エンドツーエンドのストレージソリューションを専門としています。保管スペースの最適化をお考えなら、Kingmore Rackingが信頼できるパートナーです。

Add: NO.409 West Jianshe Road, Economic Development Zone, Jinhu County, Jiangsu Province, China

著作権

2026@ Jiangsu Kingmore Storage Equipment Manufacturing Co., Ltd 全著作権所有。

サイトマップ

| ブログ

| Xml

| プライバシーポリシー

サポートされているネットワーク

サポートされているネットワーク